Your roof is a system of interlocking parts, and while the tiles or metal panels get all the attention, it is the smaller, less obvious components that often do the heaviest lifting. Metal roof flashing is a perfect example: it is the essential waterproof seal protecting your roof’s weakest points.

Essentially, flashing is a thin layer of metal carefully installed to guide rainwater away from joints and seams, like where your roof butts up against a chimney, a wall, or a vent pipe. Without it, you would have a guaranteed leak.

What Is Metal Roof Flashing and Why Does It Matter?

Think of metal roof flashing like the waterproof trim around a bathtub. You know that bead of sealant that stops water from seeping behind the tiles and causing rot? Flashing does the exact same job, but for your roof. It creates a crucial barrier at every seam, junction, and angle.

Even the most robust roofing materials would be useless without it. Rainwater is relentless and will always find the path of least resistance, which means it will exploit any small gap where your roof meets another structure.

This constant trickle of moisture is a recipe for disaster. It starts with damp patches on your ceilings, then progresses to rotten roof timbers and, eventually, costly structural repairs that were entirely avoidable. For homeowners in Berkshire and the surrounding counties, where damp, windy weather constantly batters our homes, effective flashing is not a luxury, it is non-negotiable.

The Unsung Hero of Your Roof

Flashing is not just an add-on; it is a core part of a healthy, long-lasting roofing system. Its job is simple but critical: direct water away from vulnerable spots and safely into your gutters. This is what keeps your home dry and protected, no matter what the British weather throws at it.

The importance of quality components is being recognised across the industry. The UK roofing materials sector is growing, and we are seeing more homeowners choose durable metal roofs. This trend highlights a growing appreciation for robust systems where every part, especially metal roof flashing, plays a huge role in weather resistance.

In essence, a roof without properly installed flashing is an unfinished roof. It is like wearing a top-quality raincoat but leaving the zip completely undone in a downpour; you are just asking for trouble.

Why Quality Installation is Critical

Properly installed flashing is not just tacked on. It is fitted to allow for the natural expansion and contraction of building materials as the seasons change. An experienced roofer serving the Windsor area will make sure the flashing is secure enough to handle high winds, yet flexible enough to move with the building.

Ultimately, investing in professional flashing work buys you peace of mind. It protects your property’s value and stops small, hidden leaks from turning into major structural emergencies. If you are in Windsor, Slough, or Maidenhead and have any concerns, it is always best to consult a professional for some expert advice or a flashing inspection.

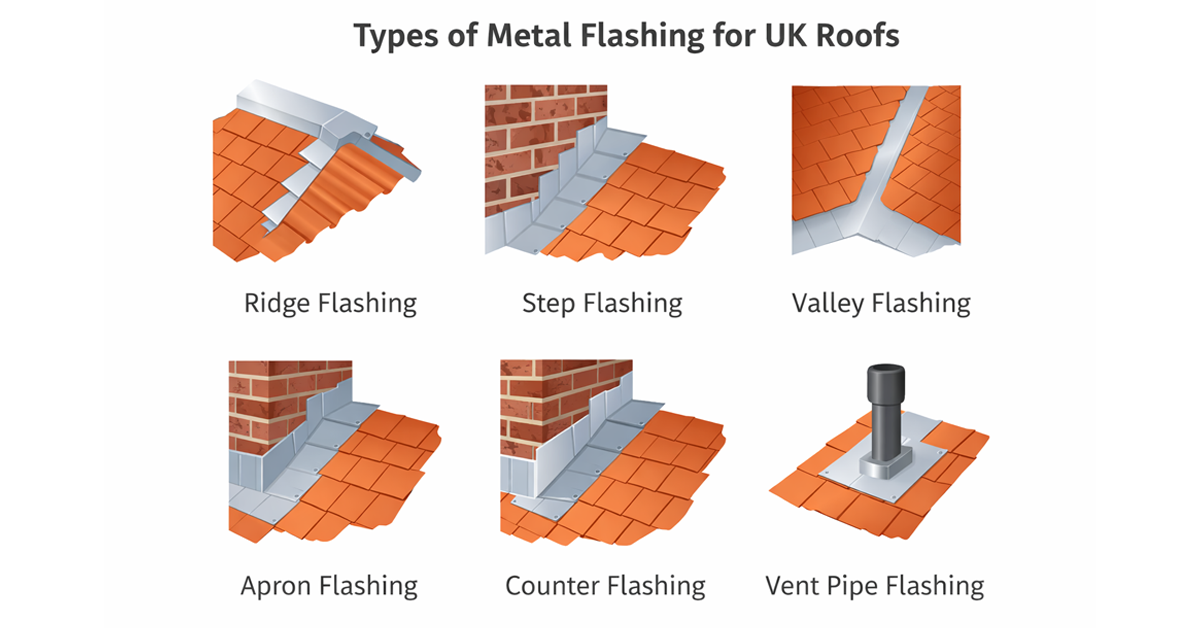

Key Types of Flashing on a Typical UK Home

To really get your head around how metal roof flashing protects your home, let’s take a quick tour of a typical British roof. Flashing is not a one-size-fits-all solution; different shapes and types are chosen for very specific jobs, all working in harmony to create a watertight shield against the UK’s famously persistent rain.

Once you can picture where each piece lives and what it does, you will be in a much better position to spot potential trouble on your own roof in Berkshire or the surrounding areas. Let’s break down some of the most common types you will find.

Step Flashing

Picture where your sloped roof runs into the vertical brickwork of a chimney or an adjoining wall. That junction is a classic weak spot for water to find its way in. To stop this, roofers use step flashing, a series of small, rectangular metal pieces installed in an overlapping sequence with the roof tiles or slates.

Each piece of flashing cleverly directs water down onto the tile just below it, essentially creating a waterproof staircase for rainwater to follow. This method is brilliant because it allows for the natural expansion and contraction between the house and the roof without breaking the seal, which is absolutely vital for handling the temperature swings we get here in Reading and Slough.

Valley Flashing

On many homes, especially those with extensions or more complex rooflines, you will see two sloped sections meeting to form a “V” shape. This channel is called a valley, and it has to handle an enormous amount of rainwater. To manage this torrent, a large, tough piece of metal known as valley flashing is installed.

This flashing acts as a waterproof gutter built right into the roof structure, making sure every drop is channelled safely down to your main guttering system. Given the heavy downpours we are no strangers to, a properly installed valley flashing is one of the most critical defences against major leaks.

A correctly fitted valley flashing is like a purpose-built canal on your roof. It is designed to handle a high-capacity flow, stopping water from overflowing and creeping under your tiles during a storm.

Chimney Flashing

Sealing the area around a chimney is one of the trickiest flashing jobs out there. It is not just one piece of metal but a complete system engineered to make the chimney base watertight on all four sides.

This system usually includes:

- Apron Flashing: A single, large piece that covers the front, downhill side of the chimney stack.

- Step Flashing: Used along the sides where the chimney meets the sloped roof, just like we discussed above.

- Back Gutter (or Back Pan): A custom-made piece that sits behind the chimney. It stops water from pooling there and diverts it safely around the sides.

- Counter Flashing: This is the final, crucial part of the puzzle. It is a second layer of flashing that is physically cut and sealed into the chimney’s mortar joints, then folded down over the top of the other flashing pieces to create a definitive, robust seal.

This multi-part system is absolutely essential to keep what is often the biggest penetration on your roof completely dry.

Other Common Types

While those are the main players, you will spot other specialised flashing around your property. Vent pipe flashing is a simple but vital cone-shaped piece that creates a tight seal around any plumbing vents that pop through your roof. For homes in towns like Bracknell and Maidenhead with lean-to extensions or dormers, apron flashing is used again to provide a clean, straightforward seal where a single sloped roof meets a vertical wall.

Of course, the world of flashing extends beyond just metal. Understanding the various roof flashing types and materials is key to total leak prevention. Contact All Custom Roofing in Windsor for expert roof repairs across Berkshire.

Choosing the Best Material for Your Roof Flashing

When you are sorting out your roof, the flashing might seem like a minor detail, but getting the material right is one of the most important calls you will make. The choice directly impacts how long your roof lasts, how it stands up to the famously unpredictable British weather, and of course, your budget. For anyone with a property in Berkshire, it is all about finding that sweet spot between durability, cost, and what works with your current roof.

Let’s walk through the most common materials we use for flashing here in the UK. Getting to grips with what makes each one different will help you have a much clearer conversation with your roofer and ensure you make a solid long-term investment, whether you are in Windsor, Reading, or one of the surrounding towns.

This diagram points out some of the key spots on a typical British home where specialist flashing is absolutely essential to stop water from getting in.

As you can see, junctions around chimneys and where two roof slopes meet are hotspots for leaks. This is why the material you choose for these areas is so critical.

To give you a clearer picture, here is a quick rundown of the main contenders for metal flashing materials, comparing what they offer in terms of performance, cost, and ideal use cases.

Comparison of Metal Flashing Materials

| Material | Average Lifespan | Pros | Cons | Best For |

|---|---|---|---|---|

| Lead | 60+ Years | Extremely durable, very flexible, corrosion-resistant, traditional aesthetic. | Most expensive, requires specialised installation, heavier than other metals. | Period properties, complex roof shapes, chimney stacks, and listed buildings. |

| Galvanised Steel | 20-30 Years | Strong, cost-effective, good rust resistance from its zinc coating. | Can corrode if the zinc coating is scratched, less flexible than lead or copper. | Modern homes, commercial buildings, long straight runs like apron flashing. |

| Aluminium | 25-40 Years | Lightweight, easy to install, naturally rust-proof, available in various colours. | Softer and more prone to denting, can react with other materials (galvanic corrosion). | General-purpose flashing, properties where weight is a concern, colour-matching. |

| Copper | 100+ Years | Phenomenal longevity, develops an attractive patina, highly durable, low maintenance. | The most expensive initial outlay, requires skilled installation. | High-end architectural homes, luxury projects, and where a “fit and forget” solution is desired. |

Each material brings something different to the table. Lead and copper are the long-life champions, perfect for prestige projects, while galvanised steel and aluminium offer fantastic, reliable performance for most modern homes.

A Closer Look at Your Options

Lead Flashing

For centuries, lead has been the gold standard for flashing in the UK, and for very good reason. It is incredibly malleable, which means a skilled roofer can shape it perfectly around all the awkward angles and tricky details on a roof, from historic chimney stacks to curved bay windows. It has an incredible lifespan, often lasting over 60 years.

Lead is still a premium choice, especially for period properties where you want to maintain that traditional look and feel. The downside? It is the most expensive option and its installation is a specialist job due to modern health and safety rules.

Galvanised Steel

If you are looking for something strong, practical, and a bit kinder on the wallet, galvanised steel is a fantastic alternative to lead. It is essentially a steel base with a protective zinc coating that shields it from rust, a must-have feature for coping with relentless UK rain.

It is a real workhorse material that provides dependable protection for decades. We see it used a lot on modern homes and commercial properties across places like Slough and Bracknell. Its rigidity makes it ideal for long, straight sections, like the apron flashing on a lean-to extension.

Aluminium

Lightweight and really versatile, aluminium is another great modern choice. It is naturally resistant to corrosion and simply does not rust, making it a low-maintenance option that performs brilliantly in our damp climate.

The main benefits are that it is easy to handle and install, more affordable than lead or copper, and can even be coated in different colours to match your roof tiles. On the other hand, it is softer than steel and can dent more easily.

A crucial point to remember is galvanic corrosion. This is an electrochemical reaction that happens when two different metals touch while wet (rainwater is the perfect catalyst). For instance, if you install copper flashing right next to galvanised steel, the steel will start to corrode very quickly. A professional roofer will always know to use the correct barriers to stop this from ever happening.

Copper

Copper is the absolute top-tier flashing material, prized for its stunning looks and incredible longevity. It comes with a serious price tag, but it can easily last for more than a century, often outliving the roof itself.

Over time, copper develops a beautiful blue-green patina, a look that is highly sought after for premium and architectural homes. In terms of durability, it is second to none, making it a true “fit and forget” solution. This level of performance and aesthetic, of course, positions copper as a luxury choice for those who want the absolute best in looks and lifespan.

Choosing the right flashing is a key part of any roofing work. To see how this decision fits into the wider context, feel free to read our guide on how to choose the best materials for your new roofing project. For advice tailored to your home in the Windsor area, do not hesitate to get in touch with us at All Custom Roofing.

How to Spot the Warning Signs of Failing Flashing

Becoming a proactive homeowner means learning to spot the subtle clues your roof sends when something is wrong. Your metal roof flashing is no exception. Catching the early warning signs of failure can mean the difference between a simple, affordable repair and widespread damage to your home’s timber and insulation.

The good news is, you do not have to be a roofing expert to see the first signs of trouble. Many are visible right from the ground, especially after the heavy rain or strong winds we often get across Berkshire. Knowing what to look for lets you act fast, stopping a small issue from turning into a major leak.

External Signs Visible from the Ground

You can get a pretty good idea of your flashing’s health without ever stepping on a ladder. A quick walk around your property, paying close attention to vulnerable spots like chimneys, walls, and skylights, can reveal a lot.

Here are the key red flags to watch for from the outside:

- Ugly Rust Stains: See any reddish-brown streaks running down your roof tiles, brickwork, or render? That is a massive clue. It means the protective coating on galvanised steel flashing has worn away, exposing the raw steel to moisture and allowing it to corrode.

- Visible Gaps or Cracks: Take a close look at the edges where flashing meets brickwork or the roof surface. If you can see daylight peeking through, or the sealant looks cracked and is peeling away, then the watertight seal is broken.

- Bent, Loose, or Lifted Sections: After a bout of strong winds, it is common for sections of flashing to lift up or get bent out of shape. This creates a perfect entry point for wind-driven rain to get underneath, completely bypassing the flashing’s defences.

Flashing failure is not just about age; it is often a result of constant exposure to the elements. The cycle of rain, frost, and sun we experience in the UK causes materials to expand and contract, which can gradually weaken seals and fasteners over time.

Internal Clues You Cannot Ignore

Sometimes, the first sign of a problem pops up inside your home. These internal warnings are serious because they mean water has already breached your roof’s defences and is seeping into your property’s structure.

Keep an eye out for these internal symptoms:

- Damp Patches or Stains on Ceilings: Brownish or yellow stains on the ceiling, especially near a chimney breast or in the corners of a room, are a classic sign of a flashing leak.

- Peeling Paint or Wallpaper: When excess moisture seeps through plasterboard, it causes paint and wallpaper to bubble, peel, or blister. Do not just paint over it; find the source.

- A Musty Smell in Upper Rooms: A persistent damp or musty odour, particularly in your loft or top-floor rooms, often points to a slow, hidden leak that is causing mould to grow out of sight within the roof space.

Why Catching It Early Matters

Regularly checking for these signs, especially after severe weather, is a simple yet effective part of good property care. For more advice on keeping your roof in top shape, check out our guide on essential tips for metal roof maintenance.

If you spot any of these warning signs at your home in Windsor, Maidenhead, or Bracknell, it is time to act. Contact All Custom Roofing for an expert assessment. We can diagnose the problem accurately and advise on the best course of action to protect your home.

Should You Repair or Replace Your Damaged Flashing?

So you have spotted a problem with your metal roof flashing. Now comes the big question every property owner in Berkshire eventually faces: do you repair it or replace it? It is a classic dilemma, and the right answer really depends on the scale of the damage, how old the flashing is, and what your long-term plans are for the property.

Sometimes, a straightforward, targeted repair is all you need. A small, isolated issue can often be sorted out quickly and affordably by a professional, stopping a minor problem in its tracks and buying you valuable time before a full replacement is on the cards.

But it is crucial to know when a quick fix is just papering over the cracks. Trying to patch up widespread or severe damage is often a false economy. Worse, it can trap moisture and quietly make the underlying problem a whole lot worse.

When a Repair Might Be Enough

A repair is usually a good shout for minor, localised damage. If you have caught a small issue early, a professional fix can restore your flashing’s integrity without the expense of a full replacement. Think of it like getting a chip in your windscreen sorted before it spiders across the whole pane.

Consider a repair in these scenarios:

- Small Cracks or Holes: A tiny crack in a metal seam or a small puncture from a falling branch can often be sorted with a high-grade, specialist roofing sealant.

- A Single Loose Fastener: If one nail or screw has worked its way loose but the flashing itself is still in good shape, it can usually be re-secured without much fuss.

- Minor Sealant Failure: The sealant around the edges of flashing can sometimes give up before the metal does. In these cases, simply cutting away the old sealant and applying a fresh, professional-grade bead can be a very effective solution.

When You Must Replace Your Flashing

While repairs are great for small jobs, there are plenty of times when replacement is the only responsible option. Trying to patch up seriously compromised flashing is like putting a plaster on a broken bone: it will not solve the fundamental issue and usually leads to much bigger headaches down the line.

A full replacement is almost always the answer for the following:

- Widespread Corrosion: If you see rust spreading across large sections of your steel flashing, its protective coating has failed. The metal is now weak, brittle, and simply cannot be trusted to keep water out.

- Significant Physical Damage: After a heavy storm rolls through Windsor or Reading, you might find flashing that is badly bent, torn, or has large sections missing entirely. This kind of structural damage is beyond a simple repair.

- Flashing Pulled Away from a Wall: If the metal has pulled away from the brickwork of a chimney or wall, creating a significant gap, the entire seal is broken. This points to a major failure that needs a complete replacement to fix properly.

- During a Re-roofing Project: If you are already replacing your roof tiles or slates, it is the perfect time to install brand-new flashing. It is the most cost-effective way to do it, and putting old flashing on a brand-new roof just does not make sense.

A Critical Warning: A common but dangerous bodge is to slather a thick layer of roofing cement or sealant over failing flashing. This tactic often traps moisture underneath, which then accelerates rot in your roof timbers and creates a far more serious and expensive problem to solve later on.

Making the right call between a quick fix and a complete overhaul is crucial. To help you understand this in the broader context of property maintenance, you might be interested in our article on making the choice between roofing repairs and a full roof replacement. If you need an expert opinion for your home in Slough, Bracknell, or Maidenhead, contact All Custom Roofing. We will give you an honest assessment and recommend the best long-term solution for your property.

Why You Should Always Hire a Professional for Flashing Work

While the satisfaction of a DIY project is undeniable, installing or repairing metal roof flashing is one job where cutting corners can lead to disastrous consequences. It is a precise, highly-skilled task where even a tiny mistake can create a persistent leak that is a nightmare to trace and fix. In fact, incorrect installation is one of the leading causes of roof leaks right across the UK.

A professional roofer brings much more than just a ladder and some tools. They have a deep, practical understanding of how water behaves, from a gentle drizzle to the kind of wind-driven downpours we see all too often across Berkshire. They know exactly how to cut, shape, and seal the metal to work with your home’s natural expansion and contraction, creating a watertight fit that lasts for decades.

The Risks of DIY Flashing Work

Attempting flashing work without proper training and gear is not just risky for your property; it is incredibly dangerous for you. Working at height carries a significant risk of serious injury. Professionals are trained in safety protocols and come equipped with the correct scaffolding and fall arrest systems to work safely on your roof.

Beyond personal safety, it is the technical details that truly matter. A pro knows the correct overlap for step flashing, how to form a perfect, watertight back-pan for a chimney, and the right way to create a lasting seal around a vent pipe. A skilled roofer also has a deep understanding of construction principles, including the critical aspect of choosing the right fasteners and fittings to ensure a secure and durable installation.

Vetting Your Local Roofing Contractor

Finding the right expert in the Windsor area is the key to a quality finish. Before you hire anyone for flashing work, it is worth arming yourself with the right questions to make sure you are choosing a true professional.

Here is a checklist of essential questions to ask:

- What is your experience? Be specific. Ask about their experience with metal roof flashing and with your particular roofing material, whether it is slate, tile, or something else.

- Do you offer a guarantee? A reputable roofer will always stand behind their work with a solid guarantee. Ask how long it lasts and exactly what it covers.

- Can you provide local references? Ask if they can show you examples of similar work they have completed nearby in Windsor, Slough, or Maidenhead.

- Are you fully insured? Always confirm they have both public liability and employer’s liability insurance. This protects you, your property, and their team.

Hiring an expert is not an expense; it is an investment in your property’s long-term health. A professionally installed flashing system provides peace of mind that your home is protected from the elements, saving you from future stress and expense.

For a professional assessment and a quality finish you can trust, contact All Custom Roofing. We cover Windsor, Reading, Slough, Bracknell, Maidenhead, and surrounding towns.

Your Metal Roof Flashing Questions Answered

To wrap things up, let’s tackle some of the most common questions homeowners in Berkshire and the surrounding areas ask about metal roof flashing. Think of this as your quick-reference guide for those nagging queries about keeping your property protected.

How Long Does Metal Flashing Last?

This really comes down to the material used. Traditional lead and premium copper are the undisputed champions here, often lasting 60 years or more, sometimes they even outlive the roof itself!

Your more modern options, like galvanised steel and aluminium, will give you a solid 20 to 40 years of reliable protection. But here is the key: regular roof inspections are vital. They help you spot trouble early and get the most out of your flashing, no matter what it is made of.

Remember, these lifespans assume a professional installation. A poorly fitted premium material will fail much faster than a standard one that has been installed correctly. A secure fit is every bit as important as the metal itself.

Should New Flashing Go Over Old Flashing?

That is a definite no from any professional roofer. Just covering up old, damaged flashing is asking for trouble. It is a shortcut that almost always traps moisture between the layers, hiding underlying rot and speeding up decay in your roof’s timber structure.

This method creates a poor seal and often causes the new installation to fail prematurely. For a watertight, long-term solution that you can actually rely on, the old flashing must be completely removed before any new flashing is fitted. No exceptions.

What Is The Best Flashing Material?

For centuries, lead has been the go-to choice across the UK. It is prized for its incredible durability and how easy it is to mould, making it perfect for shaping around the tricky angles you find on older properties. It is still a superb, long-lasting option, but it is not your only one.

Modern alternatives like high-grade aluminium and specialised coated steel offer excellent performance and can be a bit friendlier on the wallet. The “best” material really depends on your specific roof, your budget, and the architectural style of your home in Windsor or the neighbouring areas.

If you have more questions or need a professional assessment of your roof’s flashing, All Custom Roofing is here to help. We provide expert roofing services across Windsor, Reading, Slough, Bracknell, Maidenhead, and surrounding towns. Contact us today for a clear, no-obligation quote at https://customroofing.co.uk.