Staring at a technical code like BS EN 13501-1 can feel like trying to read another language. But don’t worry, it’s simpler than it looks.

Think of it like the energy efficiency sticker on a new fridge—it’s a straightforward grading system for a very complex and important topic: how construction materials react to fire. That includes everything on your roof.

What This Fire Safety Standard Means for Your UK Roof

For property owners in Windsor, Berkshire, and the surrounding areas, getting to grips with BS EN 13501-1 isn’t just a technical detail. It’s a core part of making sure your home or business is safe, legally compliant, and properly insured. The standard gives a detailed, scientific breakdown of a material’s fire performance, which is absolutely vital for protecting people and property.

This modern standard was brought in to replace older, less thorough systems, creating a much more rigorous approach to fire safety in UK construction. The switch to BS EN 13501-1 was a massive turning point, especially after the tragedy at Grenfell Tower. The old BS 476 standard was largely phased out in favour of this more demanding European system, marking a watershed moment in how the UK handles fire safety by giving a far more realistic picture of how materials actually behave in a fire.

Why It Matters for Your Roofing Project

Whether you’re planning a small repair or a full-on roof replacement, the materials you use have to meet specific fire safety criteria. This is to ensure they won’t add fuel to a fire and help it spread.

Here’s why sticking to the standard is so important:

- Legal Compliance: Using correctly rated materials is a non-negotiable part of meeting current UK Building Regulations.

- Enhanced Safety: It offers proven protection for everyone inside the property by limiting how much materials can contribute to a fire’s growth and the smoke it produces.

- Insurance Validity: If the worst happens and you have a fire, a compliant roof could be the difference between a successful insurance claim and a rejected one.

- Property Value: A professionally installed, certified, and safe roof is a huge asset that protects your long-term investment.

Understanding these ratings is key, and you can dive deeper with our guide on the top-tier Class A1 fire rating for roofing to see how safety is categorised.

Contact All Custom Roofing in Windsor for expert advice on making sure your project is safe and compliant.

Breaking Down The Euroclass Ratings From A1 To F

At the very heart of BS EN 13501-1 is its straightforward, ladder-like grading system, known as the Euroclass ratings. This system sorts materials based on their reaction to fire, assigning a grade from A1 (the absolute best) right down to F (the worst). For anyone planning a roofing project in the UK, getting to grips with these grades is the first step towards a safe, compliant installation.

Think of it like the food hygiene ratings you see on a restaurant door. The Euroclass system does the same job for your roofing materials, telling you exactly how they’ll perform if a fire breaks out. This isn’t just a tick-box exercise; it’s a critical indicator of how much a material could contribute to spreading flames.

The diagram below shows how UK Building Regulations rely on standards like BS EN 13501-1 to ensure your roof is safe.

This hierarchy makes it clear: the safety of your property is built on official regulations, which are put into practice through specific technical standards that dictate how materials must perform.

Euroclass Fire Ratings At A Glance

To make this easier to digest, here’s a quick reference table that breaks down the main fire ratings, what they mean in a real-world fire, and some common roofing materials you’ll find in each class.

| Euroclass Rating | Performance in a Fire | Typical UK Roofing Materials |

|---|---|---|

| A1 | Completely Non-Combustible. Will not contribute to a fire. | Natural Slate, Metal Sheets (Steel, Aluminium), Concrete Tiles |

| A2 | Limited Combustibility. Negligible contribution to fire. | Fibre Cement Slates, Certain Coated Metals |

| B | Very Limited Contribution. Minimal flame spread. | High-Performance Membranes, Fire-Retardant Treated Timber |

| C | Limited Contribution. Noticeable flame spread. | Some Modified Bitumen Felts, Certain Plywoods |

| D | Medium Contribution. Significant flame spread. | Untreated Timber Shingles, Some Rigid Foam Insulations |

| E | High Contribution. Very significant flame spread. | Certain Plastic Sheeting, Low-Density Foam Insulation |

| F | Easily Flammable. No performance determined. | Untreated Thatch, Materials That Fail All Tests |

This table gives you a solid starting point for evaluating a product’s fire safety credentials before you make any decisions.

The Best Performers: A1 And A2

Materials rated A1 are completely non-combustible. That means they simply will not contribute to a fire, period. Think of materials like natural slate, concrete tiles, or metal roofing sheets—they just won’t burn.

Just one step down is A2, which signifies materials with limited combustibility. They might make a tiny contribution to a fire, but their performance is still exceptionally high and considered safe for virtually any application. Many high-quality fibre cement slates fall into this category.

For any residential or commercial building, specifying materials rated A1 or A2 offers the highest possible level of assurance. These products are the foundation of a fire-resilient roof.

The Middle Ground: B To E

As we move down the scale, the materials become progressively more combustible and will play a bigger role in a fire.

- Class B: These materials have a very limited contribution to fire. You’ll find high-performance roofing membranes and some fire-retardant treated timbers achieving this rating.

- Class C: Products with this rating have a limited but noticeable contribution to fire spread.

- Class D & E: These materials have a medium to high contribution to fire. Certain types of untreated timber or plastics used in roofing would likely fall into these lower categories.

The Lowest Rating: F

Finally, we have Class F. This is the lowest possible rating and is given to materials that are easily flammable or for which no fire performance has been determined at all. Products in this class should never be used where UK Building Regulations require any level of fire resistance.

Understanding these classifications is absolutely crucial. For example, the fire rating of insulation within your roof structure is just as important as the outer covering. A properly specified, compliant system works together as a whole to protect your property.

Why Smoke and Droplet Ratings Are So Important

A material’s main Euroclass fire rating (from A1 down to F) tells a crucial part of the story, but it’s not the whole picture. When a fire breaks out, it’s often not just the flames that pose the biggest threat. Two other factors are just as vital and are covered by the BS EN 13501-1 standard: how much smoke is produced and whether the material creates flaming droplets.

In a real fire, smoke is the silent killer. It can fill a space in minutes, cutting visibility to near zero, causing total disorientation, and leading to smoke inhalation—the primary cause of fire-related deaths. The standard tackles this with an ‘s’ rating.

At the same time, you have to worry about flaming droplets. These are like tiny fireballs that can fall from a burning ceiling or roof, spreading the fire downwards to furniture, flooring, or anything else flammable. Worse, they create a serious hazard for anyone trying to get out. This is measured with a ‘d’ rating.

Getting to grips with these extra classifications is essential if you want to be sure the materials used on your property are genuinely safe.

Decoding the ‘s’ for Smoke Classification

The smoke production rating is a critical safety metric. It tells you exactly how much smoke a material will pump out when it burns, which directly impacts whether people can see enough to evacuate safely.

There are three levels to watch out for:

- s1: This is the best you can get. It means the material produces very little or no smoke. This is the gold standard for escape routes and high-risk areas where clear visibility is non-negotiable.

- s2: This rating means the material produces an average amount of smoke. While it might be acceptable in some situations, it’s a noticeable step down from s1.

- s3: The lowest rating. This is given to materials that churn out a high volume of smoke, creating incredibly dangerous conditions in a fire.

The technical difference between these is huge. To get an s1 classification, a material’s smoke growth rate must be 30 m²s⁻² or less, with total smoke production under 50 m² within 10 minutes. An s2 rating, by contrast, allows for a smoke growth rate up to 180 m²s⁻². It’s worth taking a moment to learn more about how these classifications replaced older, less detailed standards like Class 0 and why they are so vital for modern building safety.

Understanding the ‘d’ for Droplet Classification

The flaming droplet rating tells you how a material behaves when things get really hot. Will it start dripping molten plastic or raining down burning fragments? This is a key factor in stopping a fire from spreading.

Just like the smoke rating, the ‘d’ classification has three levels:

- d0: The top rating. This means no flaming droplets or particles are produced at all. The material won’t drip fire onto whatever is below it.

- d1: This indicates that some flaming droplets might be produced, but they burn out within 10 seconds.

- d2: This is the worst-case scenario. Flaming droplets are produced and they keep burning for more than 10 seconds, posing a massive risk of spreading the fire.

A complete fire rating will always include all three parts: the main Euroclass, the smoke rating, and the droplet rating. A top-performing product would be rated something like B-s1, d0. A poor performer might be rated D-s3, d2. The difference in safety is immense.

For any roofing project, from a home in Woking to a commercial building in Maidenhead, specifying materials with s1 and d0 ratings provides the highest possible level of protection. At All Custom Roofing, we always prioritise materials that offer this complete safety profile.

How Roofing Materials Earn Their Fire Rating

A Euroclass fire rating isn’t some sticker slapped onto a product at the end of a production line. It’s a hard-won badge of honour, earned only after a material survives a series of rigorous, standardised tests. Understanding how materials prove their mettle under the BS EN 13501-1 standard helps build trust, showing that these ratings are based on solid science, not just a manufacturer’s claims.

The whole process is designed to mimic real-world fire scenarios, measuring precisely how a material reacts when things get hot. It’s far from a simple pass/fail; the tests collect detailed data on every aspect of performance. This is why when you see a rating like B-s1, d0, you can be confident that the product has genuinely earned that high level of safety in controlled lab conditions.

This scientific approach is exactly why it’s so important to work with a professional contractor who gets the technical side of things. They can ensure the materials protecting your home are genuinely as safe as their certificate says they are.

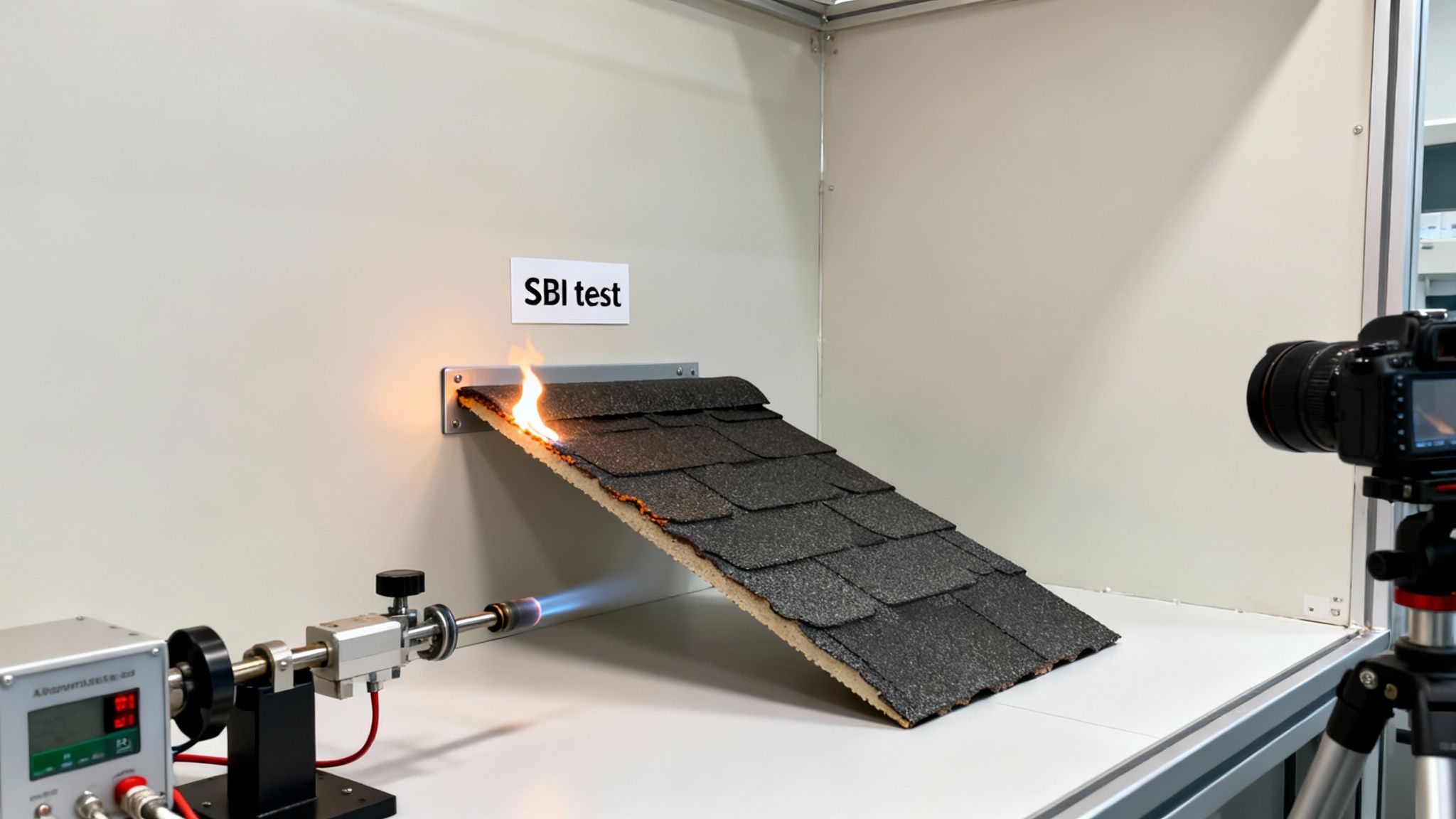

The Single Burning Item Test Explained

For most building products, the cornerstone of the Euroclass system is the Single Burning Item (SBI) test, known officially as EN 13823. This is the main event, the test that determines the primary Euroclass (from B down to D) and those crucial smoke and droplet classifications.

Think of it as a controlled experiment that simulates a small fire kicking off in the corner of a room, directly hitting your roofing material. In the lab, two panels of the product are set up in a corner formation inside a special chamber. Then, a sand-box burner providing a consistent, predictable flame is placed at the bottom.

Over the next 20 minutes or so, a battery of sophisticated sensors gets to work, meticulously measuring several key performance indicators:

- Heat Release Rate: Does the material just sit there, or does it actively add fuel and energy to the fire?

- Flame Spread: How quickly and how far do flames travel across the surface of the material?

- Smoke Production: What’s the total volume of smoke being pumped out over the course of the test?

- Flaming Droplets: Human observers watch carefully to see if any burning particles or droplets fall from the material, which could spread the fire below.

The data pulled from the SBI test is what directly translates into the classifications we see on product spec sheets. It’s a transparent, highly regulated process that leaves no room for guesswork, giving you clear proof of a material’s reaction-to-fire performance.

Additional Tests for Ultimate Safety

While the SBI test is the workhorse of the system, other tests come into play for materials at the very top and bottom of the scale. For a product to achieve the coveted A1 (non-combustible) rating, it has to pass even tougher trials.

One of these is the non-combustibility test (EN ISO 1182), where a sample of the material is shoved into a furnace heated to a blistering 750°C. The goal is to prove it won’t contribute to a fire in any meaningful way, even under extreme heat.

This rigorous, multi-test approach ensures that every single classification is accurate and reliable. Knowing this process is in place should give homeowners in Windsor and beyond real confidence that the materials protecting their property are verifiably safe. Choosing the right products is a vital first step, and you can learn more about how to choose the best materials for your new roofing project in our in-depth guide.

Meeting Your Fire Safety and Building Regulation Duties

As a property owner in the UK, you have a legal responsibility to keep your building safe, and that absolutely includes its fire performance. This is where the technical jargon of BS EN 13501-1 crosses over into your real-world duties, mainly through a government rulebook called Approved Document B (Fire Safety).

Think of Approved Document B as the official guide to fire safety in UK Building Regulations. It sets the minimum standards for how buildings should be constructed to prevent fires and ensure people can escape safely. It’s not just for brand-new builds; it’s just as important when you’re making changes to an existing property.

So, if you’re planning an extension, carrying out a full roof replacement, or even just switching the type of covering on your roof, you have to meet today’s fire safety standards. The rules are there to make sure any new work doesn’t weaken the building’s overall safety.

When Are Fire Ratings Legally Required?

For roofing projects in Berkshire, Surrey, and the surrounding areas, the need to meet these regulations is usually triggered when the work is considered a “material alteration.” You can’t just ignore it.

Here are a few common scenarios where the rules kick in:

- Boundary Proximity: If your roof is very close to your property’s boundary line, the regulations get much stricter. This is to stop a fire from easily jumping from your house to your neighbour’s. In these situations, a high Euroclass rating isn’t just a good idea—it’s a legal must-have.

- Roof Replacements: When you strip an old roof right back to its structure and install a completely new system, those new materials must meet the standards in Approved Document B. You can’t just swap old, non-compliant materials for new ones that also fall short.

- Extensions and Conversions: Building a new extension or converting your loft means the new roof structure and its covering must follow modern fire safety rules. This includes the BS EN 13501-1 classification of all the products being used.

Trying to cut corners here can backfire badly. If building control discovers non-compliant work, they can order you to rip it all out and start again—a hugely expensive mistake.

But there’s a bigger risk. Using materials that don’t meet the legal standard can have a devastating effect on your building’s insurance. If a fire does break out and the investigation finds the roofing materials weren’t up to code, your insurer could have grounds to invalidate your entire policy. That would leave you facing the catastrophic financial loss all on your own.

How to Verify Your Project is Compliant

Making sure your roofing project is fully compliant doesn’t have to be a nightmare. It’s all about being proactive and asking your contractor the right questions from the very beginning. They should be your partner in this, ready to provide clear proof.

When you’re discussing materials with your roofer, make sure you:

- Request the Technical Data Sheet: Every legitimate construction product comes with a technical data sheet from the manufacturer. This document is the product’s CV, and it will clearly state the official BS EN 13501-1 Euroclass rating (e.g., B-s1, d0).

- Verify the Full Classification: Don’t just settle for “it’s Class B.” As we’ve covered, the smoke (‘s’) and flaming droplet (‘d’) ratings are hugely important for life safety. Ask for the full code and make sure you understand what it means.

- Keep Records: Always keep a copy of the product data sheets and any certificates. These documents are your evidence that you’ve done your due diligence and met your legal obligations.

Navigating these regulations can feel a bit overwhelming, but you don’t have to figure it all out alone. For complete peace of mind, your best bet is always to work with professionals who live and breathe these requirements every day.

Contact All Custom Roofing in Windsor for expert advice to ensure your project is safe, fully compliant, and built to last.

Partnering with Experts for a Safe and Compliant Roof

Navigating the world of fire safety standards can feel like a minefield, but your responsibility as a property owner is actually quite simple: hire a competent contractor who puts safety first. As we’ve seen, understanding Euroclass ratings isn’t just about ticking boxes—it’s about managing the very real risks that come from cutting corners on roofing materials. A true professional doesn’t just lay tiles; they build a complete, compliant, and fire-safe system where every single component works together.

At All Custom Roofing, we walk our clients through every step, from picking the right materials to the final inspection. We make it our business to ensure every product we use meets or goes beyond the required BS EN 13501-1 standards for your project. We sweat the technical details and compliance checks so you can have total confidence in the long-term safety of your property.

Entrusting your project to an experienced team takes the guesswork out of the equation. You get the assurance that your roof isn’t just built to stand up to the British weather, but is also fully compliant with UK Building Regulations—protecting your investment and, most importantly, the people inside.

If you’re planning a roofing project for your home or business in Windsor, Berkshire, or Surrey, don’t leave something as crucial as fire safety to chance. Contact our team at All Custom Roofing for a consultation where the focus is on quality, compliance, and your complete peace of mind. We serve homes and businesses across Berkshire, Surrey, and beyond.

Got Questions About Roof Fire Ratings? We’ve Got Answers.

Here are some quick, no-nonsense answers to the questions we hear most often about BS EN 13501-1 and UK roofing. This should help clear things up so you can make confident, compliant choices for your property.

Is Class 0 the Same as a BS EN 13501-1 Rating?

Not at all. Think of it like comparing an old MOT certificate to a modern one – they’re from two completely different eras. Class 0 is an outdated classification from the old British Standard BS 476. The current standard required under UK Building Regulations is BS EN 13501-1.

The new European standard is far more rigorous. It crucially tests for smoke production (‘s’) and flaming droplets (‘d’), two major factors in how a fire spreads and the danger it poses. The old Class 0 system didn’t account for these at all, which is why a product only rated to Class 0 simply won’t cut it for today’s fire safety requirements.

Do I Need to Worry About Fire Ratings for a Simple Roof Repair?

For a tiny repair, like replacing a single cracked tile with an identical one, it’s less of a concern. But the moment you start replacing a whole section of your roof or switching to a different material, you absolutely need to think about it.

Any new materials you introduce must comply with current Building Regulations, and that means they need a valid BS EN 13501-1 classification. Even for smaller jobs, it’s always smart to have a quick chat with a professional roofer to make sure you’re staying on the right side of the law.

How Can I Check a Roofing Product’s Fire Rating?

It should be easy to find. Manufacturers are required to state the official fire classification clearly on the product’s technical data sheet, its packaging, or on their website. You’re looking for the Euroclass rating, which will be written in a format like B-s1, d0.

Any reputable contractor will happily provide this documentation for all the materials they plan to use on your home. If they can’t, that’s a red flag. Transparency is key to ensuring your roof is safe and compliant.

For expert guidance on selecting safe and compliant roofing materials, trust All Custom Roofing. We ensure every project meets the highest standards of safety and quality. Find out more at https://customroofing.co.uk.